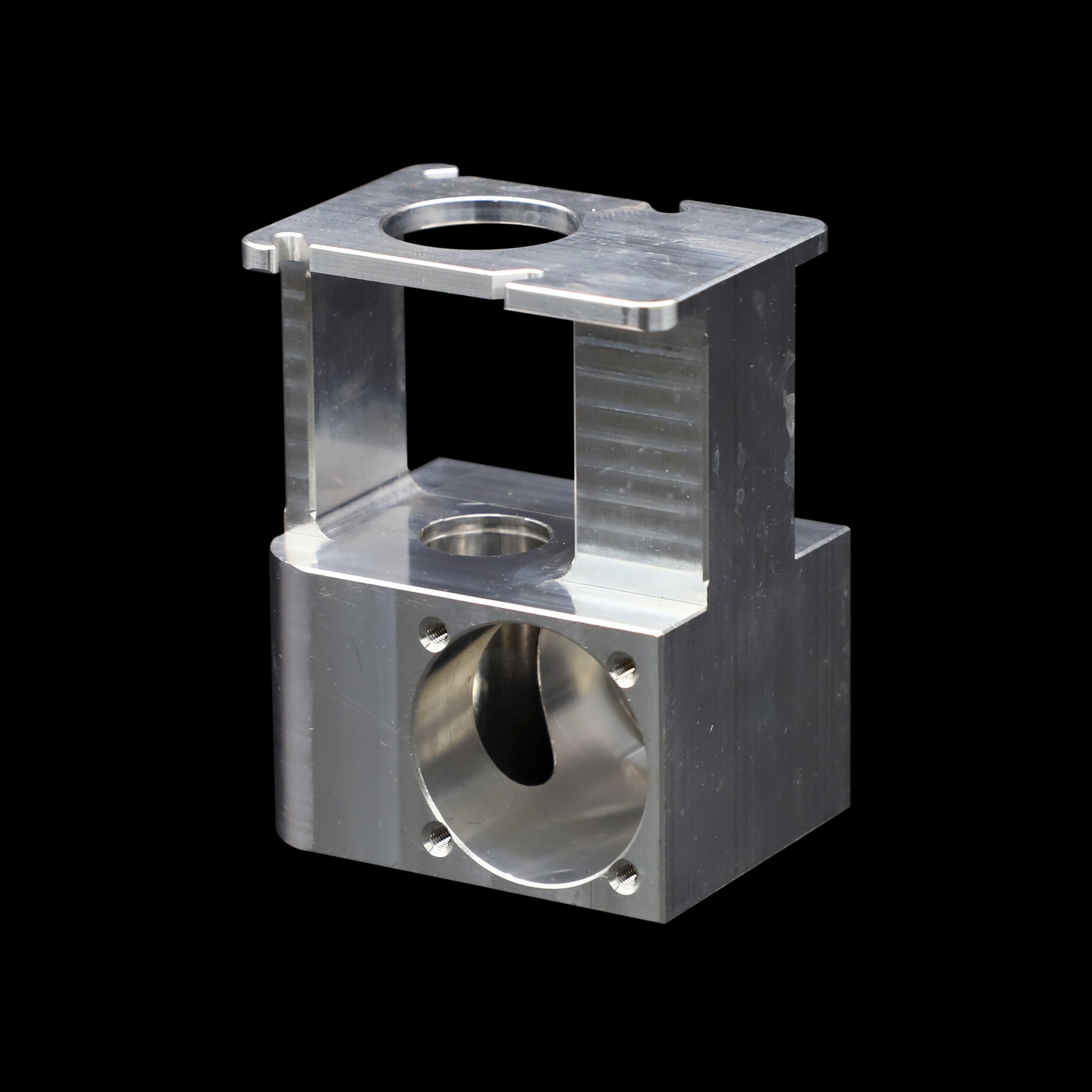

Custom CNC milling parts

What is CNC milling?

First, people often require CNC machining when looking for milling. Machining requires milling and turning, but there is a clear difference between the two. Machining refers to mechanical cutting techniques that use various tools to remove material using physical contact.

Secondly, all CNC machining uses CNC machine tools, but not all CNC machine tools are used for machining. Computer numerical control is the reason behind these three letters. Any machine using CNC uses a computerized system to automate the cutting process.

Therefore, CNC machine tools also include laser cutting machines, plasma cutting machines, and compression brakes.

Therefore, CNC machining is a mixture of these two terms, which brings us the answer to the question in the title. CNC milling is an auxiliary manufacturing method that uses computer numerical control systems to realize process automation.

| Precision Processing |

Turning, CNC Turning, Milling, Grinding, Drilling, Tapping and Machining Center |

| Applied Software |

PRO/E, Auto CAD, Solid Works, UG, CAD/CAM/CAE |

| Material |

Iron, Brass, Bronze, Titanium, Aluminum, Stainless Steel & etc. |

| Tolerance Precision |

+/-0.005~0.02mm, can also be customized. |

| Dimension |

As per customers' request |

| Part Color |

Silver, Red, Blue, Gold, Oliver, Black, White & etc. |

| Samples |

Acceptable |

| Quality System |

100% inspection before shipment |

| Lead Time |

Based on the quantity of order (Usually 10-15 days) |

| Packing |

Anti-rust Paper, Small Box and Carton, full consider of practical situation |

| Shipping |

By sea, By air, By DHL, UPS, TNT & etc. |

Milling machine type

There are many varieties on the market today. Many classification methods also exist. The basic knowledge remains almost the same everywhere, and some modifications bring more possibilities, so there is another type of milling machine.

The following are the most common types of milling machines:

bed type

Knee type

Ram type

Plane type

CNC milling operations

Milling is suitable for many different functions, including threading, chamfering, grooving, etc. This allows complex designs to be produced with enviable precision on a single CNC milling center. The tolerance of CNC machining is approximately +/- 0.1 mm.

Various milling operations are required to create the above functions:

Surface milling

Face milling

Corner milling

Form milling

Contour milling

Gear milling etc.

Suitable material

CNC milling can be used for a variety of different materials. Of course, the choice comes down to requirements. The selection process includes the following steps:

Create part geometry.

Determine the force acting on the part. Cad software and Fea add-ons may be of great help here.

Specify material properties based on the results.

Create a list of possible materials.

Choose the solution that meets the cost-benefit ratio requirements.

Make sure that the material is suitable for milling.

Metal suitable for CNC milling:

Low-carbon steel

stainless steel

Tool steel

aluminum

brass

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!