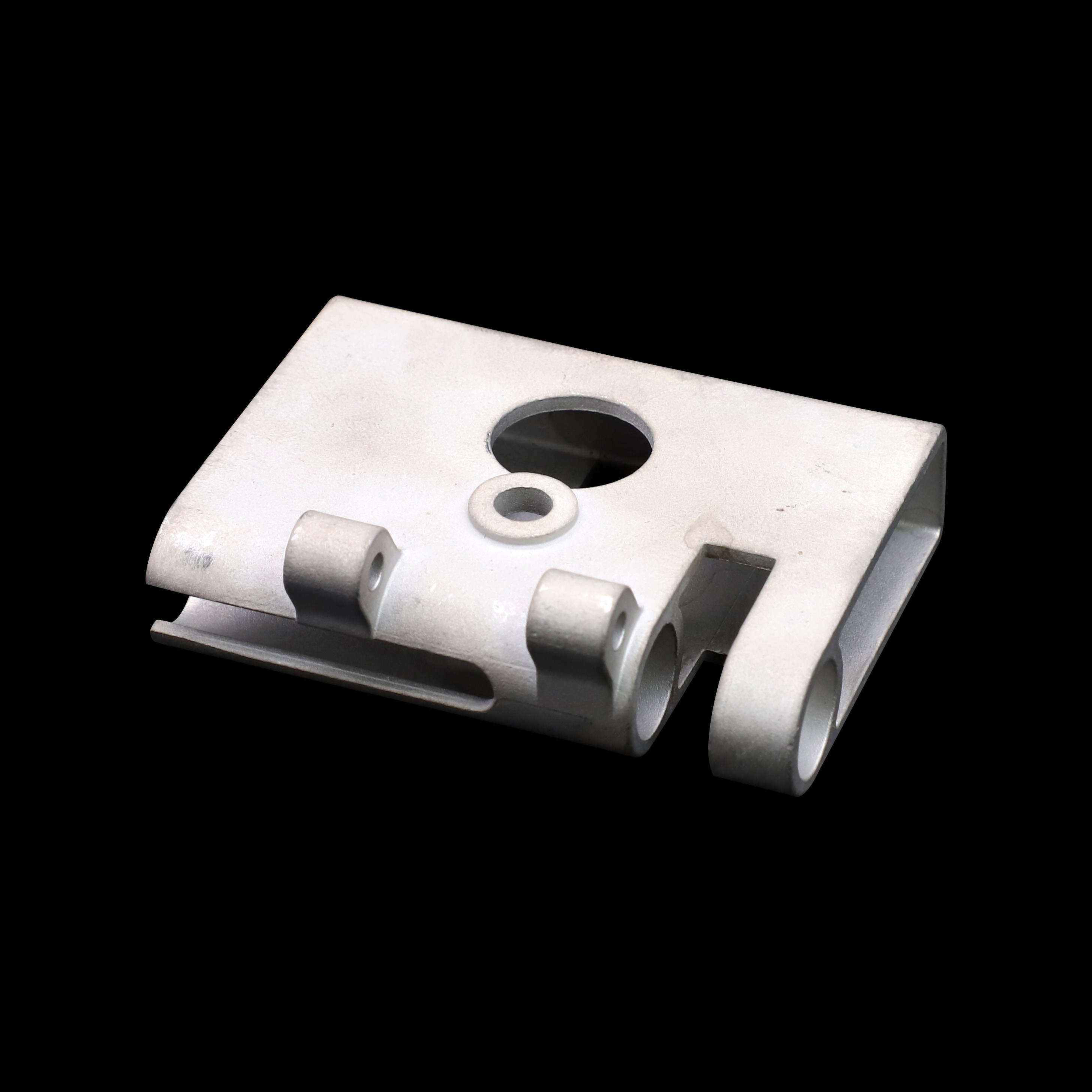

CNC tolerance 0.01mm high precision CNC machining parts

Qingdao Compass Co., Ltd. is a professional manufacturer specializing in the processing of customized high-precision hardware parts. The factory is equipped with imported advanced precision automatic lathes, CNC milling/lathes and measuring equipment, with an accuracy of 0.005mm. In addition, we have a technical team with more than 10 years of experience, which can provide reliable technical guarantees for the production of high-precision products. Our products are widely used in various industries such as optical communications, medical equipment, optics, automobiles, electronics, office, and drone parts.

Welcome to visit our factory!

Production Capacity:

| Machining Equipment: |

3/4/5 Axis CNC machining center, CNC engraving machine, CNC milling machine, CNC turning machine, high precision grinding machine, WEDM etc |

| Inspection Equipment: |

KEYENCE Image Dimension Measuring System, Projector, CMM, Height Gage, Hardness Tester, Salt Spray Tester, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

| Precision: |

Min. tolerance can reach 0.005mm |

| Application: |

Railway, Auto, Truck, Medical, Machinery, Equipment, Electronic, Electrical, Optical etc |

| Material Available: |

Aluminum: AL6061, Al6063, AL6082, AL7075, AL5052, AL2024, A380 etc

Stainless steel: SS201, 301, SS303, SS304, SS316, SS430 etc

Steel: alloy steel/ carbon steel including 4140, 4340, A36, 1020, 1045 etc

Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc.

Copper: C11000, C12000, C12000, C17200, C72900, C36000 etc.

Plastic: ABS, PC, POM, Delrin, Nylon, Teflon, PP etc.

|

|

Surface

Treatment

|

Aluminum parts: Anodization, Sandblast, Brushing, Polishing, Chrome Plating etc

Stainless Steel parts: Polishing, Brushing, Passivating, Sandblasting, PVD vacuum plating

Steel: Zinc plating, Nickel plating, Chrome plating, Powder Coating etc

Plastic: Painting, Polishing, Chrome plating, Sandblast, Engraving

|

What are the advantages of computer digital control?

All these movements rely on computer digital control, which is a computer program derived from a 3D digital file of the final part required.

Early automated machine tools relied on punch cards to systematically control their basic movements. It works, but it is a slow and cumbersome system, and once punched cards are made, they cannot be modified. Later, they were replaced by all-digital instructions in tapes, disk drives and G-Code.

The control system is not only fast and accurate, but also different from earlier systems. It can be easily modified line by line and in real time as needed to fine-tune the program to obtain the best results.

What are the benefits of automatic tool change?

Making a finished part from a piece of material requires many different tools, each of which performs a very specific machining function. Changing these tools manually at once is time-consuming and inefficient.

In order to solve this problem, the CNC milling machine has a rotating carousel, and all the required tools are pre-installed on a separate tool holder. When needed, these tools can be automatically replaced on the spindle within a few seconds.

How does CNC milling help you get quality parts?

It is best to machine basically circular or radially symmetrical parts on a CNC turning center to achieve maximum efficiency. However, most of the parts we process are not circular or symmetrical, so they must be processed on a milling machine.

CNC milled parts

Multi-axis milling machines are unmatched in creating squares, bevels, angles, grooves and complex curves-any subtractive machining process can be done on a milling machine, including making circles. They are also very precise, usually maintaining a tolerance of 0.01mm or 10 microns. We provide a variety of stock materials for any application, and provide the best incoming inspection and testing services.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!